Leading the Development of Superconductor Insulation

since 1988

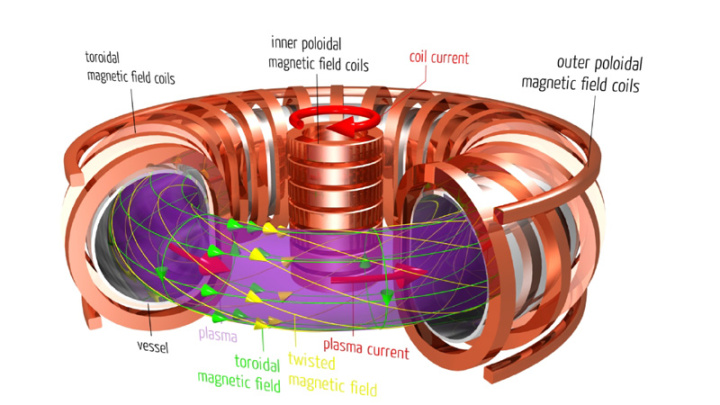

Thanks to the expertise of Dr. Naseem Munshi, the field of superconducting magnets has continued to progress and advance. There are several challenges when designing these magnets, particularly when it comes to considering all of the various factors that enable successful superconductivity. CTD’s expertise in material properties allows for the maximum magnetic field to be generated through careful shielding on the conductor against the thermal extremes of superconductivity. Within the wire itself, the high (relative) temperature to the super-cooled fluid can cause thermal cracking within the shielding and conductor, leading to magnetic quench or loss of superconductivity.

The insulation material is critical to the function of the magnet, as without the insulation the coil would fail and no magnetic field would be generated. Therefore, it is critical to fully impregnate the coil with insulation achieve superconductivity, thermal insulation, and radiation resistance for the increasing magnetic fields. CTD insulation materials underpin some of the most advanced Fusion and High Energy Physics (HEP) around the globe, each with specific material properties tailored to the application to optimize the performance of the superconducting magnet.

CTD’s family of NANUQ® Insulation will undoubtedly advance the future development of Magnetic Resonance Imaging (MRI) machines, magnetic fusion reactors, focusing magnets for particle accelerators, magnetic levitating trains (MAGLEV), railguns, electric vehicle motors, and other superconducting magnet applications, especially when space constraints demand strict attention to material properties and performance characteristics.