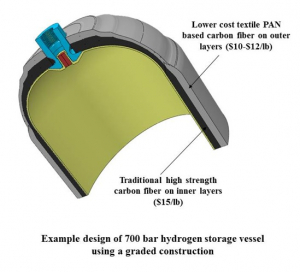

TYPE V PRESSURE VESSELS

LINER-LESS ALL COMPOSITE TANKS

Removing the liner from a composite overwrapped pressure vessel (COPV) or tank is no easy feat. Yet, CTD understands this complex process and will customize one of our Composite Pressure Vessls (CPV) for your application.

One of the key design advantages of an all-composite tank is the reduction of weight (and cost) by removing the costly liner. Additionally, our vessels won’t burst because they are designed to leak before failing, preventing destructive damage to your vehicle whether on the ground, air, or in the depths of space.

Our tanks perform well with a variety of gasses and propellants depending on your specific application and pressurization requirements.